At D&M Laser Cat, we want to turn all your ideas into extraordinary personalized merchandise and gifts. In this post, we will explain how we achieve this through custom laser cutting.

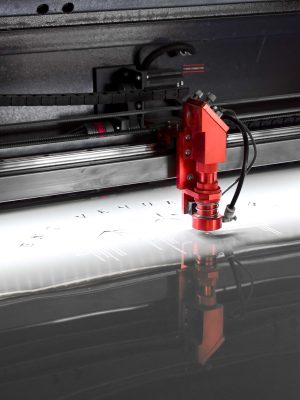

Laser cutting is a manufacturing process that uses a concentrated and focused laser beam to cut, engrave, or mark different materials such as wood, plastics, glass, ceramics, and many others. We typically prefer eco-friendly materials ❤️

Below, we are going to explain you the procedure we follow when performing our laser cutting

To begin, we need a digital design of the pattern or shape to be cut, engraved, or marked. For this, we use computer-aided design (CAD) software or graphic design software

Once we have the design, we use specific programming software to convert the design into a computer numerical control (CNC) program. This is going to guide the laser cutting throughout the entire cutting process

First, we place the material (properly leveled and secured) in the machine

Then, we adjust the laser power and head movement speed according to the material’s characteristics and the design we are following to produce the custom laser-cut piece

We focus the beam precisely on the point where the laser cutting will take place. The distance between the lens and the material must be adjusted accurately to achieve a clean and precise cut

To finish, all that’s left is to start the machine and load the program with the laser cutting instructions. The laser moves according to the coordinates specified in the CNC program!

The high energy of the laser allows us to cut through the selected material with precision and speed

After completing the cut, the result is inspected to ensure it meets the specifications and quality required by both the professional and the customer

Laser cutting is widely used in various industries because it is highly precise and versatile. This makes it a valuable ally when producing customized pieces or prototypes really quickly

As mentioned earlier, laser cutting is a fascinating technique that allows us to take personalization to the next level. With millimetric precision, we can transform pieces of wood, metal, leather, fabric, glass, and other materials into customized pieces that tell a unique story

If you’re looking for a gift for a loved one, want to surprise your employees or friends, or want to take your company’s brand to the next level, don’t hesitate to send us your idea, and we’ll be more than happy to assist you. And remember: we always offer special discounts for large orders 😉

Fill in the contact form without compromise and we will get back to you within 24 / 48 hours.

© dmlasercat | Todos los derechos reservados | Política de Privacidad | Cookies